PROJECTS

PROJECT TYPE

Improve overall and operating performance

Process automation

CLIENT

National Silicates

SECTOR

Metallurgy

REGION

Montérégie

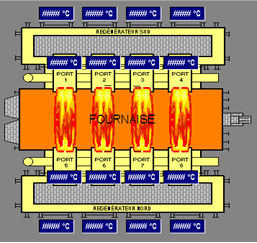

Company

As part of a project to improve the energy efficiency of its furnace, National Silicates contracted an energy engineering firm to design the retrofit required to reach its desired objectives. Because of our multidisciplinary expertise, we were commissioned to implement the control concept and measure each of the eight burners of the furnace, manage the air/gas ratio in real time, and monitor the gas pressures in real time.

Mandate

To go from concept to reality, Lem Technologies performed the following tasks:

- Designed a remote control panel to add the necessary new inputs and outputs to the existing automated controls

- Created electrical drawings for the new furnace management panel to integrate it into the plant in line with the existing electrical drawings

- Installed electrical components to connect the new gas equipment: shut-off valves, modulating valves, flow meters, pressure transmitters, temperature sensors, position switches, and pressure switches

- Analyzed the existing automated program to add real-time air/gas ratio management and pressure monitoring

- Added programming for PID control of the gas supply for each individual burner

- Improved combustion air fan speed control to ensure stability in air/gas ratio control

- Collaborated with the various parties involved (engineering firm, combustion technician, maintenance technician) to test and adjust the control loops and to restart the furnace after the retrofit was complete

Benefits

The completed furnace retrofit provided National Silicates with the following gains:

- Better combustion to save gas

- Better temperature stability for improved process performance

- Better control over the internal pressure of the furnace, reducing the frequency of repairs