PROJECTS

PROJECT TYPE

Improve overall and operating performance

Process automation

CLIENT

Plombco

SECTOR

Manufacturing

REGION

Montérégie

Company

Plombco, a major manufacturer of wheel weights for the automotive industry, produces every day more than one million weights that are sold around the world. Our client has an in-house engineering department, which is in charge of the development of its highly automated plants. Plombco, however, was considering an innovative project aimed at improving inventory management in the warehouse but was reluctant to go ahead with it because of technological uncertainties.

Mandate

The people at Plombco invited Lem Technologies in their engineering offices to present the handling and labelling project and to explain their technological uncertainties with regard to precision and speed. Thanks to its experience in movement control, Lem was able to illustrate with actual cases how it was possible to carry out the project and to meet performance expectations. Following that meeting, Lem was involved in the project and worked with the mechanical designer to develop a handling system that would fulfil the requirements.

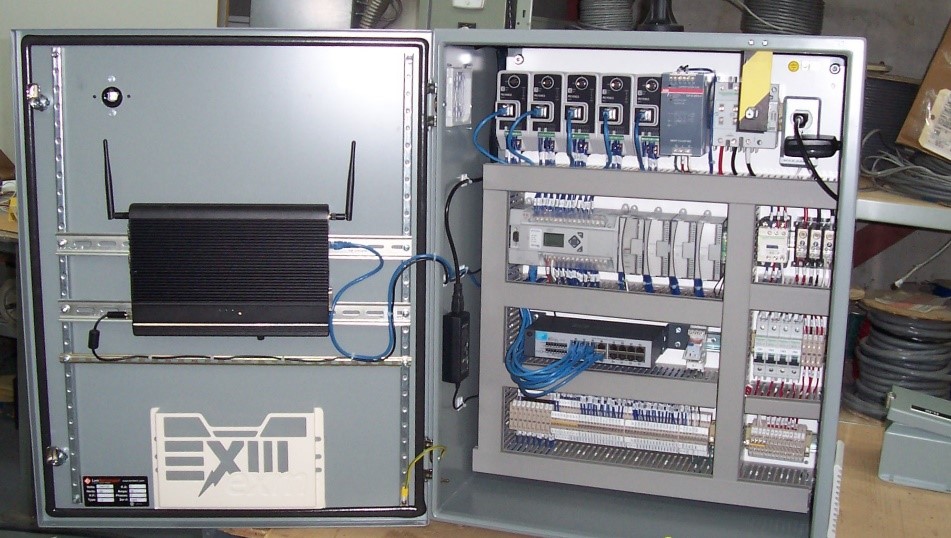

We were responsible for designing and manufacturing the control panel, and then for programming the system’s PLC in order to integrate the different technologies that were required:

- Servomotor

- Absolute encoder

- Print and apply labellers

- Database server

- Bar code reader

- Smart conveyors

- Communications network

Lem installed the control system on the manufacturer’s mechanical shop’s machine for validation testing. Once the effective functioning of the system was demonstrated, Lem took care of electrical installation and commissioning at Plombco.

Benefits

Thanks to the project, Plombco was successful in reducing inventory levels and in better managing its product shipments to distributors. Lem also transferred technological knowledge related to the project so that Plombco could be autonomous in managing the solution.